Introduction

Water scarcity and environmental pollution are two of the most pressing challenges faced by industries and communities worldwide. As freshwater resources dwindle and regulatory frameworks tighten, industries are compelled to rethink their wastewater management strategies. One of the most promising solutions gaining traction is the Zero Liquid Discharge (ZLD) system — a cutting-edge approach that aims to eliminate liquid waste discharge entirely.

At PGS Energy Services Pvt. Ltd. (PGSEPL), we recognize the growing importance of ZLD systems in achieving sustainable water management. In this blog, we explore the future of ZLD technology, its benefits, challenges, and how it can revolutionize industrial wastewater treatment.

What is Zero Liquid Discharge (ZLD)?

Zero Liquid Discharge (ZLD) is a wastewater treatment process designed to recover almost all the water from industrial effluents, leaving behind only solid waste (usually salts or sludge). The treated water is recycled and reused within the industrial process, ensuring no liquid discharge into the environment.

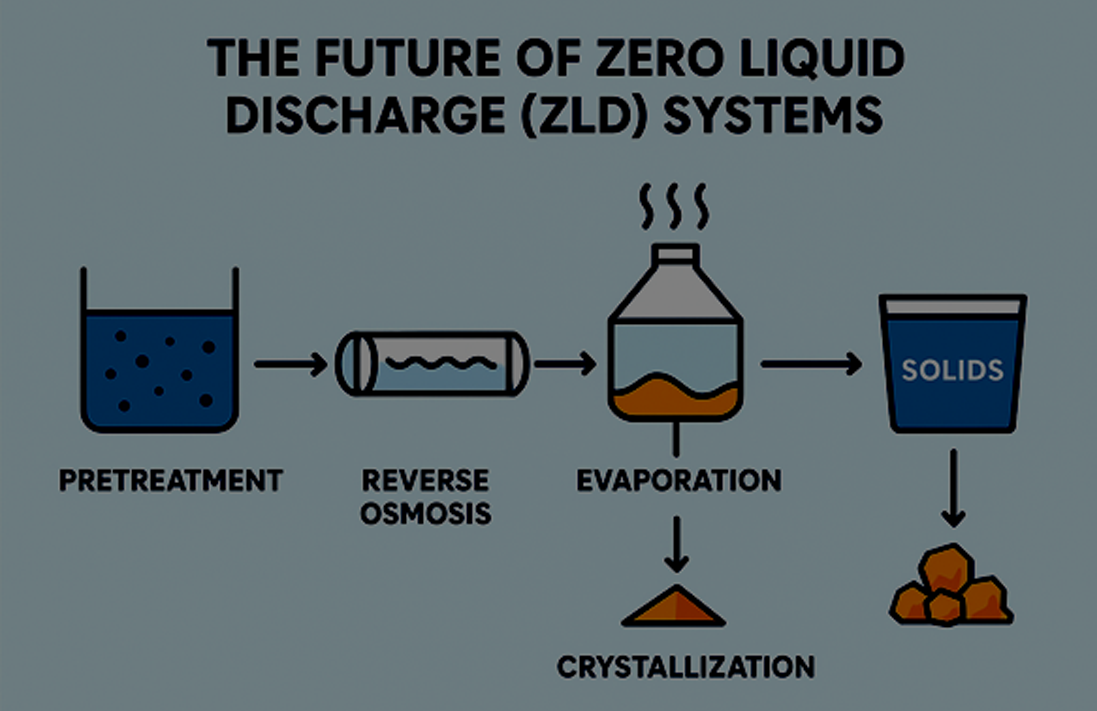

The ZLD system typically combines multiple treatment technologies, such as:

- Pre-treatment: Removal of suspended solids and contaminants.

- Evaporation and Crystallization: Concentrating wastewater to recover clean water and solid residues.

- Membrane Filtration: Reverse osmosis or nanofiltration to separate dissolved solids.

By achieving near-total recovery, ZLD systems help industries comply with stringent environmental norms while promoting water conservation.

Why ZLD is the Future of Wastewater Management

1. Rising Water Scarcity

With growing global water scarcity, industries must maximize water reuse. ZLD enables industries to recycle nearly 100% of wastewater, reducing dependency on freshwater sources and safeguarding critical water reserves.

2. Stringent Environmental Regulations

Governments worldwide are enforcing stricter wastewater discharge limits to protect water bodies from pollution. ZLD offers a reliable pathway for industries to meet and exceed these standards, avoiding penalties and enhancing corporate responsibility.

3. Sustainability and Corporate Responsibility

ESG (Environmental, Social, and Governance) frameworks increasingly emphasize responsible water stewardship. Adopting ZLD showcases an organization’s commitment to sustainability, boosting stakeholder trust and brand reputation.

4. Technological Advancements

Advances in membrane technology, evaporation systems, and automation are making ZLD systems more energy-efficient, cost-effective, and adaptable to various industrial scales and wastewater types.

Applications of ZLD Systems

ZLD technology is particularly valuable in industries with high water usage and complex wastewater, including:

- Textile and Dyeing

- Pharmaceuticals

- Power Plants

- Oil & Gas and Petrochemicals

- Chemical Manufacturing

- Tanneries

- Food and Beverage

- Any Energy Intensive Sectors

These industries generate wastewater containing heavy metals, dyes, salts, and organic compounds, making conventional treatment insufficient.

Challenges and the Road Ahead

Despite its benefits, ZLD adoption faces several challenges:

1. High Capital and Operational Costs

ZLD systems require significant investment in infrastructure and energy. However, ongoing innovations are gradually reducing these costs, and companies can realize long-term savings through water reuse and regulatory compliance.

2. Energy Consumption: Evaporation and crystallization are energy-intensive processes. Integration with renewable energy sources and energy recovery systems is key to improving sustainability.

3. Complex Waste Management

Handling and disposal of solid residues need to be managed responsibly to avoid secondary pollution.

PGSEPL’s Role in Advancing ZLD Solutions

At PGSEPL, we provide expert consultancy and turnkey solutions for ZLD implementation. Our services include:

- Feasibility Studies and Audits

- Customized ZLD System Design

- Installation, Commissioning, and Maintenance

- Energy Optimization and Integration with Renewable Sources

- Regulatory Compliance Support

Our goal is to help industries transition smoothly towards zero liquid discharge, minimizing environmental impact while maximizing operational efficiency.

Conclusion

The future of industrial wastewater management lies in innovative, sustainable technologies like Zero Liquid Discharge. As water scarcity intensifies and environmental norms become more rigorous, ZLD systems will be central to responsible water stewardship.

Industries that embrace ZLD not only protect precious water resources but also position themselves as leaders in sustainability and regulatory compliance. PGSEPL is committed to supporting this transformation with expert guidance, innovative solutions, and a vision for a water-secure future.

Connect with PGSEPL Today

Explore how ZLD systems can benefit your industry and contribute to a sustainable future. Visit www.pgsepl.com or contact us for expert consultancy and solutions.